Operating A Cold Storage Warehouse? Check Out Our Fire Safety Alternatives

Why fire prevention technology is superior to sprinkler systems

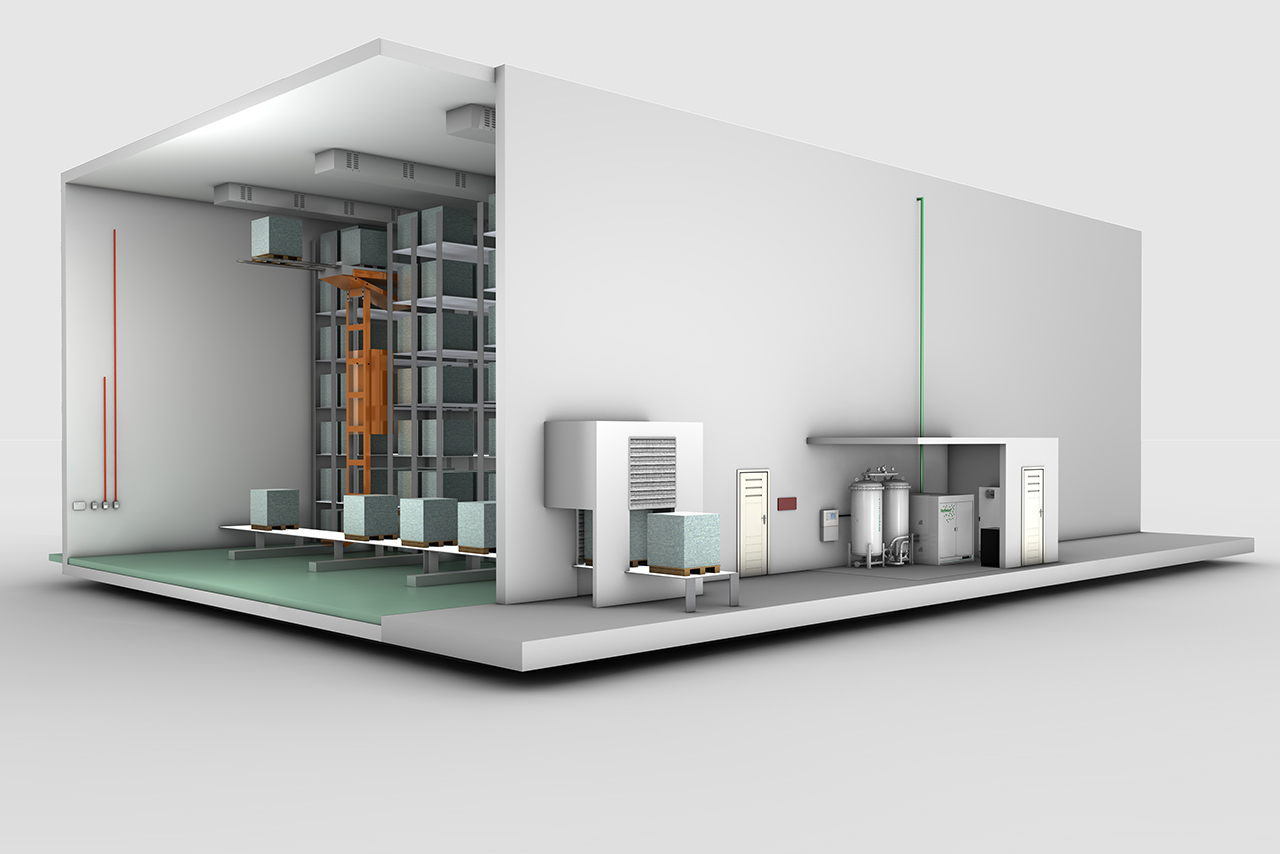

Operators of cold storage facilities know the inherent dangers of their working environment. They need fire safety alternatives that can withstand extreme thermal conditions to effectively protect people, property and processes.

So far, many have relied on sprinkler systems, the

de facto standard in the U.S. But these conventional fire safety solutions have the following downsides:

- Slow to respond, they are inadequate for modern high-rack storage warehouses exceeding 100 ft. in height.

- Reactive rather than proactive, they are only triggered once a fire has started and destruction is well underway.

- They use extinguishing agents, usually water mixed with antifreeze, that cause irrevocable damage to stored goods - accounting for major supply chain disruptions.

- Burst sprinkler water pipes and false alarms can cause damage even when there is no fire in sight.

- They require valuable space for their water tanks and supplies of extinguishing agents.

It’s no wonder then that solutions like OxyReduct® - preventing fire rather than controlling or suppressing it - are becoming increasingly popular in the U.S. cold storage industry and beyond.

How OxyReduct® doubles down on fire in cold storage settings

OxyReduct® prevents fires in cold storage facilities by carefully reducing the level of ambient oxygen in the protected area to below the ignition threshold of the stored materials, and replacing it with nitrogen. Since nitrogen is a natural component of the ambient air – it actually makes up 78% of the air we breathe – it has no negative effects on stockpiled goods, usually food products. What’s more: in high rack storage facilities OxyReduct® can be maintained in a very energy-efficient manner.

With OxyReduct®, cold storage warehouse facilities remain safe and safely accessible to authorized personnel.

Cold storage fire prevention: legal requirements

Warehouse operators in general, and operators of cold storage facilities in particular, are required to be compliant with all their local fire safety codes. These codes differ by jurisdiction, but all aim to ensure the safety of people, property and the environment.

Building code requirements, for example, mandate fire protection measures such as preventing a fire from breaking out, limiting its spread, and ensuring easy access to fire departments with the overarching objective of protecting life, health and livelihoods. Insurance carriers typically require cold storage warehouse operators to take additional measures to prevent damage to property and ensure seamless business continuity.

In addition to these requirements, warehouse owners and operators have to consider the specific needs of their facility.

To find the best possible fire protection solution for your cold storage facility, you must first create a customized fire safety concept. The NFPA 1620 standard provides guidelines for developing such concepts “to maximize protection for occupants, responding personnel, property and the environment.” Fire safety experts can provide invaluable help with this important task. Involved in the conceptual stages of facility planning, they can design fire prevention concepts that not only meet building and insurance requirements, but are also tailored to your warehouse’s specific needs.

Cold storage fire safety alternatives include very early fire detection

OxyReduct® works in conjunction with TITANUS®, our line of air sampling smoke detectors. A single detection unit is connected to a network of pipes that includes air-sampling points. The detector uses vacuum pressure to draw continuous samples from the ambient air and examines them for the smallest traces of smoke particles for earliest possible fire detection. TITANUS® is designed for use in sub-zero temperatures and can be equipped with optional features such as dust filters, three-stage alarms and patented air sampling point clips that resist ice formation.

TITANUS® air sampling smoke detectors are both false-alarm proof and hypersensitive - up to 2,000 times more sensitive than conventional point-type detectors. The system detects nascent fires at the earliest possible stage, even in difficult-to-access areas such as along storage racks or at great heights.

The largest single cold storage facility in North America, Preferred Freezer Services, features OxyReduct® as its main fire prevention solution in its Seattle, WA warehouse.

Why WAGNER?

WAGNER is the number-one specialist in innovative, individual fire protection concepts. Our expertise is reflected in the large-scale international projects we have realised for customers like apetito, Eisbär, Coppenrath & Wiese, and Dr. Oetker.

Combining systems

With VisuLAN you can centrally monitor and manage your technology, communication and security systems from a single console - effectively minimizing safety hazards and accelerating response times in case of an emergency.