Warehouse Fire Prevention, Detection and Supression

How WAGNER systems ensure fire safety in warehouse and storage environments

WAGNER’s solutions for fire prevention are particularly popular across the warehouse and logistics sector, where the risk of fire is high and where water and other extinguishing agents can cause devastating damage.

Unlike conventional warehouse fire suppression systems, such as sprinklers, OxyReduct® does not fight fires, but rather prevents them from starting. It reduces oxygen levels in protected areas to just below the point at which a fire can ignite, effectively protecting people, products and business processes.

OxyReduct® can be combined with TITANUS®, WAGNER's powerful fire detection technology. TITANUS® is 2,000 times more sensitive to smoke than conventional smoke detectors. Not only does TITANUS® save valuable time in the event of a fire threat, it also avoids false alarms thanks to its integrated filters, LOGIC∙SENS® intelligent signal processing and drift compensation.

Fire protection planning for the warehouse and logistics sector

When building or expanding a warehouse, effective pre-fire planning is imperative. There are, of course, basic local building code requirements and additional measures mandated by insurance carriers. But all this is rarely enough. Truly effective fire protection planning takes the specific needs of the warehouse operator into account.

Since no two-warehouse facilities are the same, it is also essential for pre-fire plans to be customized. That’s where WAGNER’s fire safety experts come in. Involved in the conceptual stages of warehouse planning, they help design fire protection concepts that not only meet code and insurance requirements, but are also tailored to meet individual facility needs.

Perfectly coordinated warehouse fire protection

Fire protection can only succeed if the solution’s technical, structural and organizational aspects work in sync, synergistically reinforcing one another. Warehouse operators need careful, expert fire prevention, detection and suppression planning if they want to devise a system that is both efficient and economical, and avoid costly rework.

Warehouse fire suppression: legal requirements

Warehouse operators are required to be compliant with all local fire safety codes. These codes differ by jurisdiction, but all are designed to protect people, property and the environment. The NFPA 1620 standard provides guidelines “for developing pre-incident plans to help responders effectively manage emergencies so as to maximize protection for occupants, responding personnel, property and the environment.”

Different fire protection concept for different types of storage facilities

Each type of rack storage facility, whether automated high-bay, hazmat, or cold storage, comes with its own fire safety hazards and requires its own unique approach to fire safety planning.

Mini-load automated warehouse facilities, for example, are packed with plastic containers whose fire behavior resembles that of burning petrol. In cold storage facilities, on the other hand, extreme temperatures, dry air and highly combustible packaging materials all exacerbate the spread of fire.

Why WAGNER?

As experienced systems engineers, WAGNER specialises in planning and designing fire prevention systems for warehouses and logistics centres. The company numbers among the global technology leaders in the fire prevention sector.

High-quality, tested, and certified warehouse fire safety solutions

At WAGNER, we develop leading-edge technologies and products consistently setting the global gold standard for fire prevention. Our in-house R&D and engineering department has developed over 700 patents to date, and all our systems are tested and certified.

WAGNER is especially proud to be certified by VdS, Europe’s #1 independent body for fire safety. The VdS is also in charge of DIN, ISO and EN inspections and certifications.

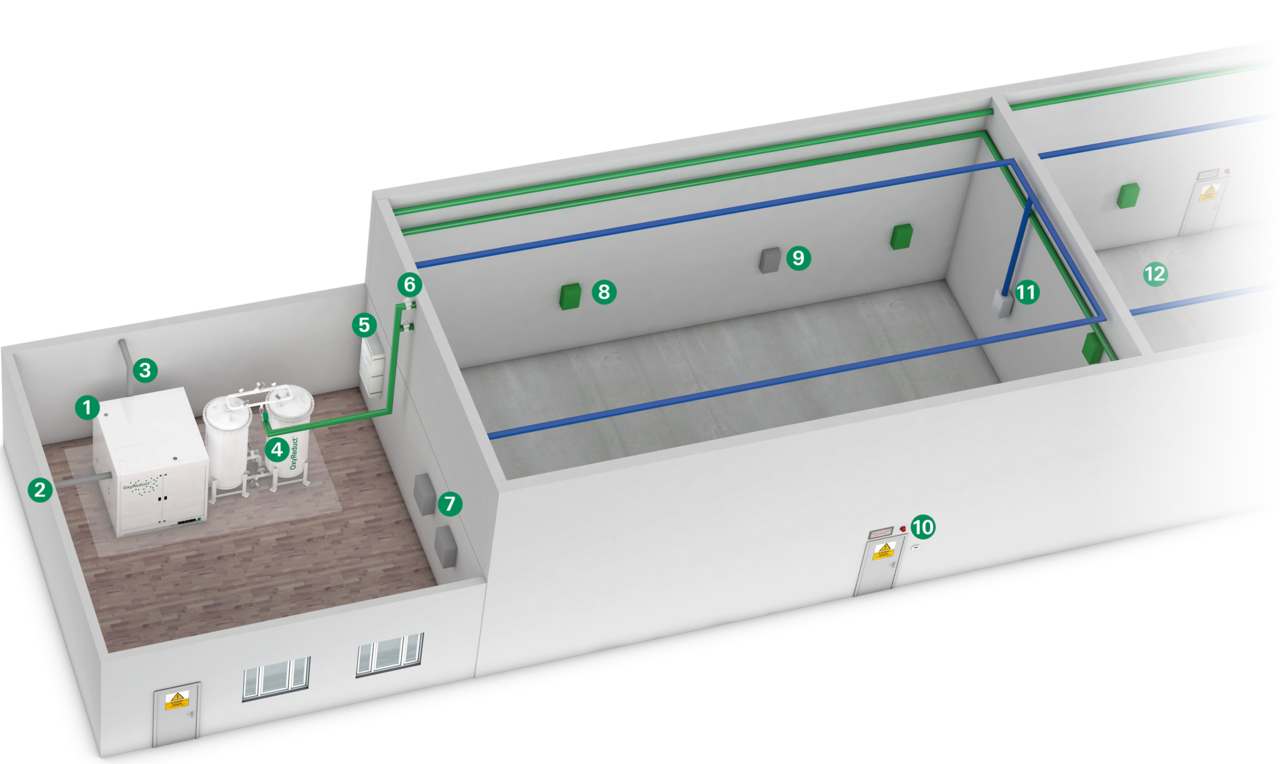

1 OxyReduct® generator (VPSA technology): Extracts nitrogen from ambient air and uses it to reduce oxygen concentration in protected area

2 Supply air (ambient air)

3 Exhaust air (O2)

4 N2 in-feed pipe: Introduces nitrogen into the protected area, where it is distributed via air recirculation system

5 OxyControl central controller: Manages all OxyReduct® processes 6 Selector valve: Opens/closes nitrogen supply valves for specific areas

7 Area regulator 1 and 2: Work in conjunction with OxyControl to monitor oxygen content in the air and adjust it to pre-defined protection levels

8 OXY-SENS® O2 Sensor: Continuously measures oxygen concentration levels in protected area

9 OXY-SENS® SIL2 Sensor: Provides additional oxygen concentration measurements and activates sector valve closure when levels drop below 12%

10 Area display: Shows the current oxygen concentration levels in the protected area

11 TITANUS®: Highly-sensitive air sampling smoke detector

12 Multi-faceted protection concepts: To keep protected areas accessible as needed (unrestricted access for authorized personnel, restricted for maintenance staff); may include multiple protection layers and deploy various oxygen concentration levels

Combining systems

With VisuLAN risk management, you can centrally monitor and manage multiple technical, communication and security systems from a single console, minimizing security risks and accelerating response times in case of an emergency.